Inventory

Transactions: Oracle Inventory, with Oracle Order Entry, Oracle Purchasing

& Oracle WIP, provides you with a complete set of transactions &

reports for maintaining inventory control. This allows you to control the flow

of material from the time you receive items to the time you ship finished goods

to the customers.

Mainly used Inventory Transactions are:

1.) Miscellaneous

Transactions : These are used to adjust inventory items quantity

2.) Move

Order Transactions

3.) Inter

Organization Transfer (Transactions)

4.) Account

Issue or Account Receipts

In order to perform any Inventory Transactions, first check

if Inventory periods are open.

Navigate to Accounting Close Cycle > Inventory Accounting

Periods

Click on Change Status for Jul-12 & Aug-12

Now Navigate to Transactions > Miscellaneous Transaction

Miscellaneous Receipt: In order to add Inventory Items in

our Sub Inventory, we make use of Miscellaneous Receipt.

Click on Transaction Lines. Add details as shown below &

Save the record.

Check On-Hand Quantity

Navigate to On-Hand, Availability > On-Hand Quantity

Give Search Criteria as shown below

Click on Find & then on Availability

Miscellaneous Issues: It is use to decrement the inventory

stock

Navigate to Transactions > Miscellaneous Transaction

Check for On Hand Availability

If you want to check Transaction Summary Navigate to

Transactions > Transaction Summaries

Give details as shown below

click on Summarize

Click on Transaction Details

Move Order Transaction: It is used to transfer the goods

from one Store (Sub Inventory) to other within an Inventory Organization. This

can be done Manually. It includes following 4 steps

1.) Move

Order Creation

2.) Move

Order Approval

3.) Move

Order Allocation

4.) Transact

Move Order

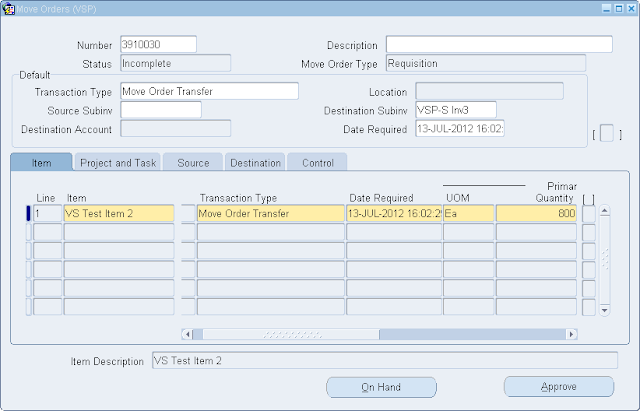

Navigation Move Orders > Move Orders

Click on Number field & Tab Out. Give Details as shown

below

Save it & click on Approve

Now Navigate to Move Orders > Transact Move Orders

Give Move Order Number & click on Find

Check the Select Check box & click on Allocate.

Next is to generate a Pick Slip. For that Submit a Single

Request ‘Move Order Pick Slip’ & give Move Order Number as Parameter

Once the request completes successfully, check the output

file

This Slip will be handed over to Store Manager & Now the

material will be transacted. In order to record this movement in system, go

back to Transact Move Order form & click on Transact

Now we Have total of 700 items in Sub Inventory 1 & 200

in Sub Inventory 2. In case if we want to move a total of 800 to Sub Inventory

3 then we can do that as well.

Navigate to Move Orders > Move Orders

Fill details as shown below (Source SubInv field is blank)

Save it & Approve

Navigate to Transact Move Order form

Search for the Move Order Number

If you want to View or Update Allocations that can also be

done. Once Done save it & click on Allocate

Now you can check the On Hand Availability in all the 3 Sub

Inventories

This comment has been removed by the author.

ReplyDeleteOn hand quantity is increasing for me..whether we have to do sub inventory transactions first or Miscellanous transaction first

ReplyDeleteTell me your issue in detail

Deletehow a move order is approved automatically? is it approved by system automatically or user approved. please explain in detail. thanks in advance

ReplyDeleteHmm is anyone else experiencing problems with the pictures

ReplyDeleteon this blog loading? I'm tryig to find outt if its a problem on my end oor if it's

the blog. Any feed-back would bee greatly appreciated.